If you have ever had to tell a customer, “Sorry, we are out of stock,” you know how quickly trust can slip away. On the flip side, overordering can leave you with shelves full of unsold products and money tied up in storage

For years, businesses tried to solve this with spreadsheets, endless phone calls, and crossed fingers. The problem? Manual inventory management moves too slowly for today’s market. When your supply chain has multiple moving parts warehouses, suppliers, online stores, and retail outlets even a small delay in updating stock levels can throw everything off.

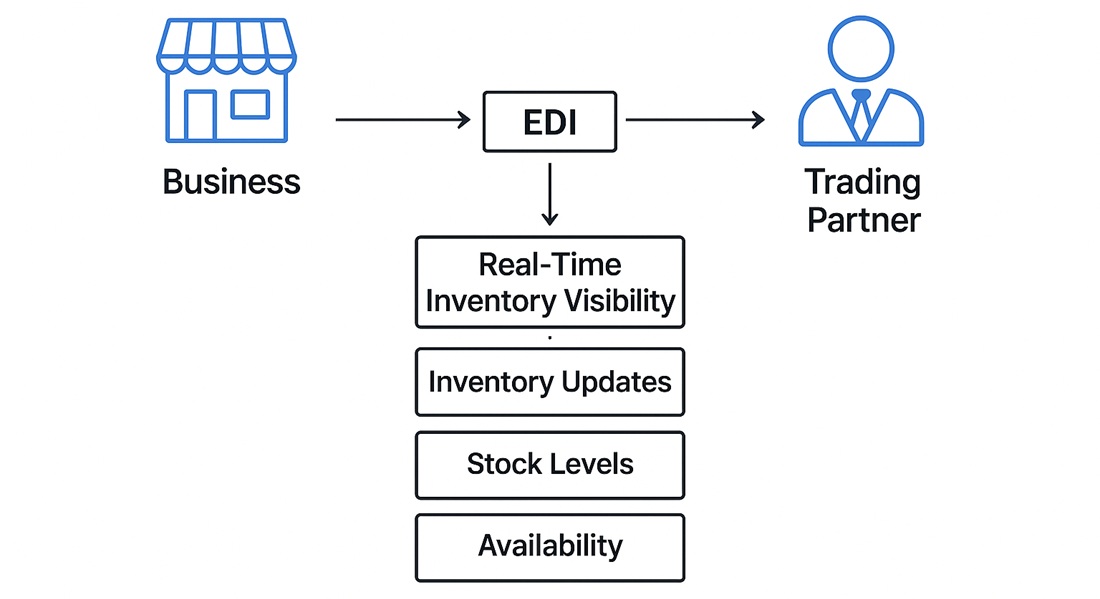

That is where Electronic Data Interchange comes in.

EDI: The Translator for Your Supply Chain

At its core, EDI is like a universal translator for your business systems. It takes your inventory data, purchase orders, shipping notices, and invoices, and sends them directly to your trading partners’ systems automatically, in the exact format they need.

Instead of waiting hours (or days) for an email reply or a phone call, EDI updates your partners in real time. A warehouse ships 500 units? Everyone from your supplier to your retail team sees the change instantly.

This kind of speed and accuracy is exactly what modern inventory management needs.

Why Manual Tracking Falls Short

Manual inventory tracking might have worked back when business moved slower when you had a few products, a few sales channels, and plenty of time to react. But that is not the world we live in anymore.

Today, one product could be selling in your shop, on Amazon, through your website, and maybe even to wholesale buyers overseas all at the same time. If your systems are not talking to each other, it is like trying to run a race with one shoe untied.

Here is what usually happens without EDI:

- You run out of stock before you realize it, because the reorder never got sent in time.

- You end up with a warehouse full of slow-moving items, because sales data did not get updated fast enough.

- You spend hours fixing mistakes caused by someone typing the wrong number into a spreadsheet.

With EDI, those headaches disappear. Your inventory levels update automatically everywhere, so your team and your partners always know exactly what is in stock.

Real-Time Inventory Visibility

One of the biggest EDI advantages is real time stock visibility. Through standard EDI transactions like the EDI 846 Inventory Inquiry/Advice, you and your partners can check accurate inventory counts before placing orders.

This means:

- Retailers are not stuck apologizing to customers because they sold something that is no longer in stock.

- Suppliers can get products moving before you even think to pick up the phone.

- Your team can ditch the endless error fixing and focus on actually getting orders out the door.

Multi-Channel Selling Made Simple

If you sell through multiple channels, you have probably dealt with the nightmare of double-selling a product or losing a sale because you thought an item was out of stock.

EDI solves this by updating stock levels across every channel instantly. Sell one item online? Your in-store inventory updates right away. Ship from one warehouse? Your other locations know immediately.

This real-time sync helps you confidently take on more sales channels without the fear of overselling or disappointing customers.

Beyond Inventory Counts

When EDI is connected to your ERP or warehouse management system, inventory data becomes more than just numbers. It turns into business intelligence.

With integrated EDI, you are not just moving data around. You are making smarter moves every day. You can:

- See which products are picking up, and spot when demand starts to change before it catches you off guard.

- Only order what you actually need, so you're not stuck with extra stock (or paying to store it).

- Run sales and promos based on what is really in your inventory not what you think is there.

And keep your finance and support teams in the loop without the back-and-forth emails. Everyone stays on the same page, automatically.

The Drawbacks (and Why They are Worth It)

Like any new system, EDI comes with a few speed bumps. Different partners might have their own tech quirks. Getting it set up takes time. And yes you will need to learn a bit about how the documents and codes work.

But here is the trade off: once it is up and running, EDI slashes the busywork, cuts down on mistakes, and helps you make faster, better decisions. The payoff easily outweighs the setup effort.

Looking Ahead

Inventory management is getting a serious upgrade. These days, AI can tell you what you will need before you even notice you're running low. IoT sensors track your stock in real time, and cloud tools make it easier than ever to manage everything even if you are not a big company.

But behind all the tech, EDI is still doing the quiet work. It is not just about sending files. It is what keeps your systems in sync and your supply chain running without surprises.

If you are trying to cut costs, stay on top of inventory, and keep your customers happy, having EDI work hand-in-hand with your inventory tools is not just helpful. It is a no brainer.

To learn more about how Infocon Systems can take care of your EDI needs, please don’t hesitate to give us a call at +1 888-339-0722 or email sales@infoconn.com. We’d love to hear from you.

FAQs & Quick Tips: EDI + Inventory Management

How does EDI improve inventory accuracy?

Think of EDI as your stock’s “live update” button. When sales happen or shipments arrive, your inventory adjusts instantly — no more manual entry, no more guessing what’s really in stock.

Can EDI help prevent stockouts and overstocking?

Definitely. Real-time data means you can restock fast when items start selling quickly, and slow down orders when demand dips — keeping your warehouse balanced.

Is EDI only for large companies?

Not at all. Cloud-based EDI makes it affordable and accessible for small and mid-sized businesses, without the massive IT bill.

How does EDI save time for my team?

It handles the repetitive stuff — purchase orders, shipment confirmations, and stock updates — so your team can focus on shipping orders and helping customers.

Does EDI integrate with my current software?

Most providers can plug directly into ERPs, WMS, and eCommerce platforms. A good provider will customize it to fit your workflow.

What’s the ROI of EDI for inventory management?

You’ll cut down on errors, speed up order processing, and lower storage costs — savings that stack up over time and keep your operations running smoother.