Third-party Logistic (3PL) firm is vital in the modern supply chain that moves at a great speed. Whether it be warehousing and fulfillment, or last-mile delivery, the 3PLs should be able to handle complicated operations in a fast and precise manner. In order to fulfill such demands, the high-ranking 3PLs are having to resort to Electronic Data Interchange (EDI) the technology that would automate communication amongst shippers and retailers and suppliers. Through EDI, the 3PLs have a chance of providing real-time visibility of shipments, expedited order processing and reduced manual entries.

This tutorial helps to simplify what 3PL EDI integration is, why it is necessary, and how to introduce it into the business without problems in particular, when you are expanding your eCommerce retail business.

What is 3PL EDI?

3PL EDI refers to the digital exchange of business documents between a 3PL provider and its trading partners including retailers, manufacturers, suppliers, and carriers.

Rather than transmitting paper records or manual mails, EDI facilitates communication of things like; Purchase order, Advance shipping notice, invoice, warehouse shipping records/confirmations and Functional acknowledgment.

The Complexity Behind 3PL EDI Integration

EDI integrations with 3PLs tend to be complicated because of the broad scope of the systems, formats, and protocols among various trading partners. The standards applied by each retailer or client could be different (such as ANSI X12 or EDIFACT), they might need certain kinds of document, or particular data mappings. Moreover, 3PLs are required to interface EDI Connections to internal systems like Warehouse Management Systems (WMS), Transportation Management Systems (TMS) or ERPs most of which lack native EDI support. Managing such integrations tend to be custom work that needs thorough testing and continual maintenance to match new requirements. Even these minor data structure or timing forces cannot be tolerated without the proper EDI platform or professional guidance since they may attract costly delays or aborted transactions or fines.

How Does 3PL EDI Work?

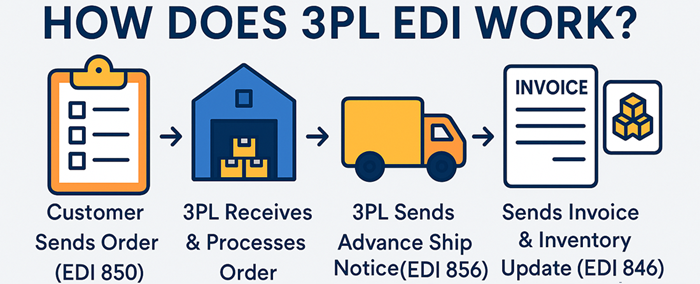

3PL EDI makes it easy for third-party logistics providers and their partners like retailers and suppliers to share data instantly and automatically. Here’s how it typically works.

when a customer places an order, they send an EDI 850 to the 3PL. The 3PL picks up that order and processes it in their Warehouse Management System (WMS). After they've shipped the order, the 3PL sends back an Advance Ship Notice (EDI 856), which provides customers with tracking information and delivery details. They may also send an invoice (EDI 810) at this point. To keep everyone in the loop, regular inventory updates (EDI 846) are shared, letting partners know current stock levels.

This smooth communication helps cut down on mistakes, speeds up order fulfillment, and gives both the 3PL and its clients better visibility. Connecting with the 3PL’s internal systems (like WMS, TMS, or ERP) makes sure all data moves accurately and automatically throughout the supply chain.

How to Implement 3PL EDI Integration (Simplified Guide)

The process of implementing EDI (Electronic Data Interchange) with your third-party logistics (3PL) partner does not have to be a daunting task. Once you establish your EDI relationship with the 3PL, the task can largely be broken into a series of steps taken at a pace commensurate with your capabilities -- purchasing new software, setting up the environment, testing, training, implementation, build-out -- everything necessary to ensure seamless communication, automation, and most importantly accurate data between your systems and those of the 3PL.

The first is to define your business requirements. Which EDI documents do you need to exchange with the 3PL? Typically you will start with the purchase order (EDI 850), a shipping notice (EDI 856), and an invoice (EDI 810) for sales orders. You also need to identify the systems involved in the integration and their connections, whether it be your ERP, warehouse management system (WMS), or eCommerce platform checklist.

After choosing an integration method based on their needs, capabilities, and growth plans, retailers may have a one way, direct EDI connection from their system to the 3PL system. Or go through a third-party value-added network (VAN), which is a managed messaging hub, typically requiring increase costs. Smaller retailers may only have been using a web-based EDI portal that does involved some manual inputs. As of recent, modern retailers are using hybrid options of EDI versus APIs, however, they typically communicate with a customer in real-time.

Once a provider has been selected, the next step is to map out the data. Retailers will need to review the populated data fields in their systems and create alignment with the data fields the 3PL systems expert requires. In one example, this may include that a retailer's order number provided in the column would be a different field in the 3PL or Vice versa. The retailer must be able to provide the correct fields so that the 3PL applies the right data and sends and/or receives the EDI format, ANSI X12 or EDIFACT, on their end.

Now that mapping is done, you'll start the integration testing. You will work with your EDI provider and your 3PL to create valid order scenarios to validate that documents are being sent and received correctly, and to correct any issues that come up. Testing is important so you can prevent problems later as you go live.

Once testing is successfully completed, you are in production. You will begin processing live transactions with the integration up and running. You should pay attention to the first few exchanges to ensure nothing fails; if possible, set up alerts to let you know if anything failed, confirmations were not returned, or something is not matching up.

Finally, as your business grows, you will also have to maintain the integration. In time, you may need to add other EDI documents (like inventory updates or return authorization) or change mappings as your systems change. Consistent auditing and performance checks, as well as talking with, your 3PL will help you continue to offer an appropriate EDI set up to fulfil your orders accurately and efficiently.

What are the common 3PL EDI transactions?

The following are examples of the most common EDI transactions that are used between 3PLs and their trading partners:

- EDI 850 (Purchase Order): sent by the customer when the customer submits a purchase order to the 3PL to fulfill their order for goods.

- EDI 940 (Warehouse Shipping Order): sent by the client to tell the 3PL warehouse to ship goods to a location.

- EDI 945 (Warehouse Shipping Advice): sent by the 3PL to tell everyone that an order has been shipped for a customer.

- EDI 856 (Advance Ship Notice - ASN): provides tracking, packaging, and delivery details and information to the trading partner.

- EDI 810 (Invoice): sent by the 3PL or vendor to request payment for products or services.

- EDI 846 (Inventory Inquiry/Advice): communicates current inventory levels from the 3PL to the client.

- EDI 997 (Functional Acknowledgment): tells the trading partner that the EDI document was received successfully.

- EDI 943 (Warehouse Stock Transfer Shipment Advice): tells the 3PL warehouse that inventory is being sent for storage.

- EDI 944 (Warehouse Stock Transfer Receipt Advice): tells the 3PL warehouse that the inventory in EDI 943 has been received.

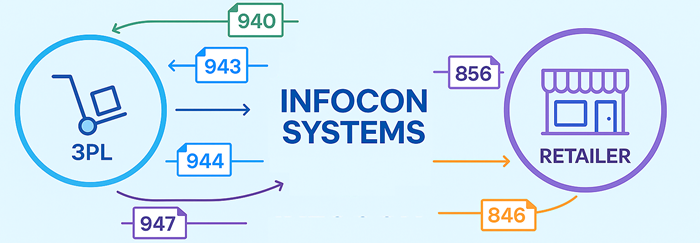

Why Choose Infocon Systems for 3PL EDI Integration?

Infocon Systems delivers a convenient, scalable, and flexible EDI solution for third-party logistics (3PL) providers and their customers. Unlike other EDI providers, Infocon has over 35 years of experience in delivering EDI and B2B integration as fully managed, cloud-based services that do not require complex infrastructures or in-house development. Infocon's platform is capable of managing all major EDI document types, including 850, 856, 810, 940, 945 and 997 allowing a seamless relationship and transaction between retailers, warehouses, and transportation providers.

One aspect of Infocon that is extremely valuable to 3PL organizations is the flexibility and customizability for integrating with almost any ERP, WMS or eCommerce platform including those of NetSuite, SAP, Microsoft Dynamics, Shopify and Amazon. Infocon's team manages the process from the initial mapping process, testing, supporting third party partner onboarding and ongoing support, 3PL's and their customers can focus on their business processes and services without worrying about compliance standards or data errors. Infocon's solutions are also in line with retail compliance standards allowing 3PL's to meet their trading partners requirements such as with Walmart, Target, Costco, etc. without risk of penalties.

In conclusion, Infocon Systems delivers a simple EDI solution for 3PL organizations with all the benefits of a hands-free, full support integration carrier that brings an affordable and future-ready option.

Contact Infocon Systems today for a free consultation and customized quote.

FAQs

Q: How long does it take to set up 3PL EDI integration?

A typical setup can take 2–6 weeks depending on complexity and testing.

Q: Can I build EDI in-house?

Yes, but it's often more efficient to use an EDI provider to handle mappings, compliance, and partner onboarding.

Q: Why do I need EDI with my 3PL provider?

EDI streamlines order processing, improves accuracy, and ensures faster communication between you and your 3PL. It also helps meet the compliance requirements of major retailers like Amazon, Walmart, and Target.